Over 25 Years Producing Custom Shutters in North Carolina

The Shutter Production began in 1986 when a window covering company hired three high school students who needed a job. The three young men worked in every aspect of the business, including repairs, installation sales, measuring, fabrication, and finishing, while also forming a close friendship. The men drew up a business plan and found a great location for their fledging enterprise in beautiful Duplin County. After years of training, working, learning, and building, The Shutter Production was born.

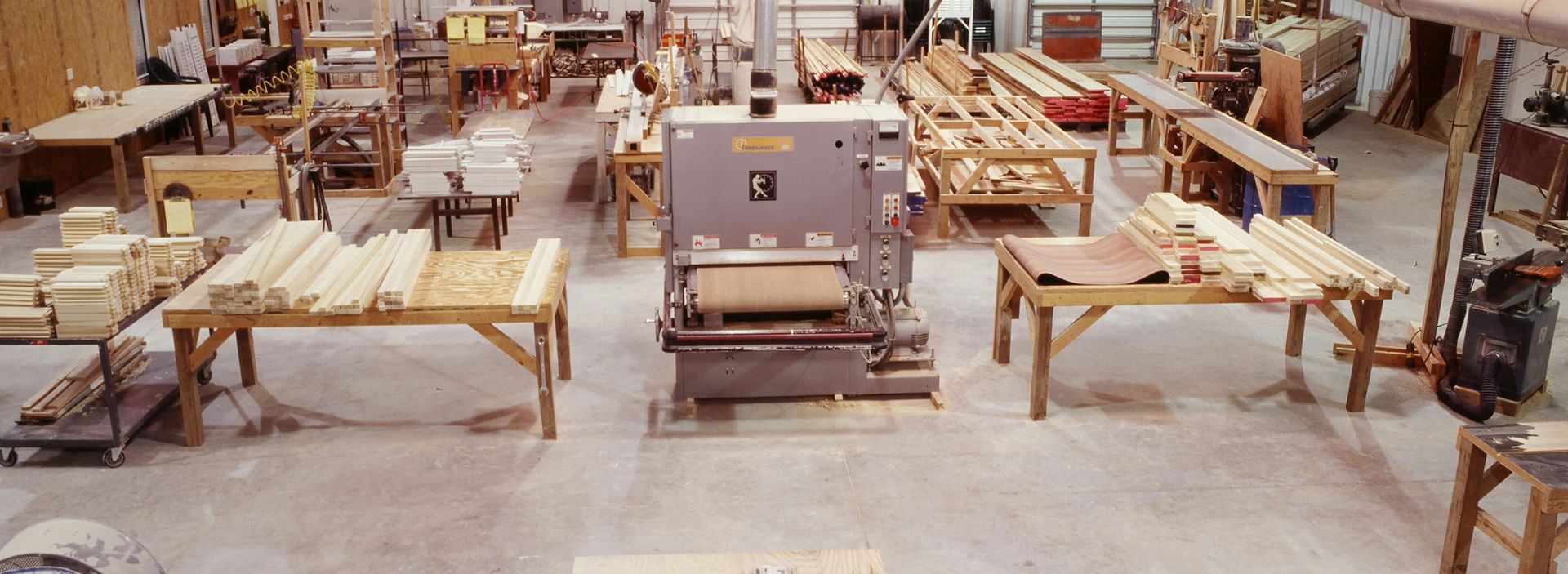

Through the years, The Shutter Production has kept almost all its original hires as well as expanded with new workers, a new facility, and state-of-the-art machinery. The Shutter Production is proud to use lumber grown and harvested in the United States and proud to be one of North Carolina’s high-quality manufacturers during a time when it seems more common to send the work to other countries.

Today, The Shutter Production specializes in residential, commercial, worship locations and the film industry. They’re committed to providing their clients with a professional experience, quality products, and extraordinary spaces.

Meet the team:

Owner/president

Andy King

OWNER/Office Manager

The Craftsmanship Behind Our Work

Our shutter components are primed, sealed, and sanded smooth. After this process, the components are assembled together.

The shutters are once again hand sanded and primed in our abrasives and finishing area. After the second coat of primer is applied, the shutters are again hand-sanded before the top color coating is applied.

We’re only a phone call away! Call 910-289-2620 to get expert recommendations for your house.